Diffusil® UV represents the fused silica grade with the highest chemical purity and the best optical homogeneity from the Diffusil® family. Only synthetically generated raw materials of the highest purity and a unique manufacturing technology are used for the production.

Diffusil®-UV has a monomodal size distribution of tiny gas bubbles with a diameter of about 4µm inside the material. With their almost perfect spherical shape, these act as ideal optical scattering centers and provide an almost Lambertian scattering characteristic. The quantity and size of the gas bubbles in the material can be adapted to customer requirements.

The material is ideally suited for use as an optical diffuser in a wide wavelength range from UV to IR wavelength.

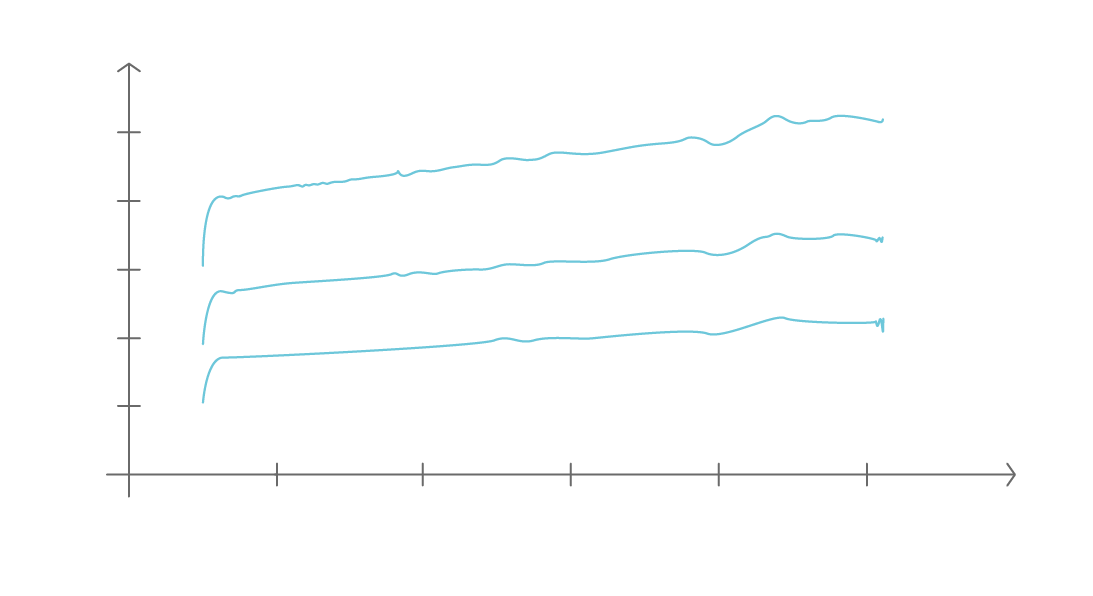

Representation of the transmission of our various UV materials depending on the wavelength.

Optical transmission of various Diffusil®-UV materials as a function of the sample thickness

Thermal Properties

| Heat conductivity | |||||||

|---|---|---|---|---|---|---|---|

| Temperature in °C | 20 | 100 | 200 | 400 | 600 | ||

| Heat conductivity W / m*K | 1,29 | 1,32 | 1,37 | 1,43 | 1,47 | ||

| Heat conductivity | |||||||

|---|---|---|---|---|---|---|---|

| Temperature in °C | Heat conductivity W / m*K | ||||||

| 20 | 1,29 | ||||||

| 100 | 1,32 | ||||||

| 200 | 1,37 | ||||||

| 400 | 1,43 | ||||||

| 600 | 1,47 | ||||||

| Thermal expansion coefficient: | 5.6 x 10-7 • K-1 (20 °C – 500 °C) |

| Softening point: | 1,610 ° C |

| Max. working temperature - short term: | 1,200 ° C |

| Max. working temperature - long term: | 1,000 ° C |

| Thermal expansion coefficient: |

| 5.6 x 10-7 • K-1 (20 °C – 500 °C) |

| Softening point: |

| 1,610 °C |

| Ma. working temperature - short term: |

| 1,200 °C |

| Max. working temperature - long term: |

| 1,000 °C |

Chemical Properties

By using high-purity, synthetically produced raw materials and subsequent cleaning steps in the production process, Diffusil®-UV achieves the highest chemical purity with very low OH content. The typical trace impurities of this material quality are shown below:

| Trace impurities [ppm / weight] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Al | Ca | Cu | Fe | K | Li | Mg | Na | Ti | Zr |

| < 0,15 | < 0,05 | < 0,02 | < 0,05 | < 0,05 | < 0,02 | < 0,02 | < 0,05 | < 0,05 | < 0,02 |

| Trace impurities [ppm / weight] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Al | < 0,15 | ||||||||

| Ca | < 0,05 | ||||||||

| Cu | < 0,02 | ||||||||

| Fe | < 0,05 | ||||||||

| K | < 0,05 | ||||||||

| Li | < 0,02 | ||||||||

| Mg | < 0,02 | ||||||||

| Na | < 0,05 | ||||||||

| Ti | < 0,05 | ||||||||

| Zr | < 0,02 | ||||||||

| OH-Content: | < 0,2 ppm / weight |

| Acid resistancy: | acc. Class 1; DIN 12 116 |

| Alkali resistancy: | acc. Class 1; DIN 52 332 |

| OH-Content: |

| < 0,2 ppm / weight |

| Acid resistancy: |

| acc. Class 1; Din 12 116 |

| Alkali resistancy: |

| acc. Class 1; DIN 52 322 |

Physical Properties

| Density: | 2,05 - 2,19 g / cm³ (depending on desired opacity) |

| Porosity: | 0,5 - 7 % non-open Porosity |

| Bubble size: | 3 - 4 µm Diameter |

| Modulus of elasticity: | 50 - 54 kN / mm² |

| Bending strength (3-point): | 80 - 84 N / mm² |

| Density: |

| 2,05 - 2,19 g / cm³ (depending on desired opacity) |

| Porosity: |

| 0,5 - 7 % non-open Porosity |

| Bubble size: |

| 3 - 4 µm Diameter |

| Modulus of elasticity: |

| 50 - 54 kN / mm² |

| Bending strength (3-point): |

| 80 - 84 N / mm² |

Optical Properties

The extremely homogeneously distributed gas bubbles in the material create the opaque visual appearance of Diffusil®-UV. They are responsible for an almost Lambertian scattered light behavior of the material. IQS offers four different opacities with modified scattered light behaviour by changing the number of bubbles:

Diffusil®-UV300: appr. 300 Million bubbles / cm³

Diffusil®-UV500: appr. 500 Million bubbles / cm³

Diffusil®-UV1000: appr. 1,000 Million bubbles / cm³

Diffusil®-UV2000: appr. 2,000 Million bubbles / cm³

The high purity of Diffusil® UV and the absence of OH-groups in the glass lead to a uniformly high transmission without disturbing optical absorption bands.

Electrical Properties

| Dielectric constant: | Electrical resistivity: |

|---|---|

| 3,70 (20°C 1· 106 Hz) | 1 x 1018 Ω • cm (20 ° C) |

| 3,77 (23°C 9 · 108 Hz) | 1 x 1010 Ω · cm (400 ° C) |

| 3,81 (23°C 3 · 1010 Hz) | 6,3 x 106 Ω · cm (800 ° C) |

| Dielectric constant: | Electrical resistivity: |

|---|---|

| 3,70 (20 °C · 106 Hz) | 1,0 x 1018 Ω • cm (20 °C) |

| 3,77 (23 °C 9 · 108 Hz) | 1,0 x 1010 Ω · cm (400 °C) |

| 3,81 (23 °C 3 · 1010 Hz) | 6,3 x 106 Ω · cm (800 °C) |

We answer your questions

Do you still have questions about the material? Please send us a message.